Roy Poage: The Grandfather of Modern Swine Production

People might have complained about his genetics, but they always tried to poach his people because they were good, says Jan Archer, a North Carolina pig farmer.

“They were well trained, and they were smart. And they are still out there because of Roy Poage,” Archer says. “He inspired people. He made them see that the pork industry is a great place to have a career and it can lead you to amazing opportunities.”

The list of reasons why the U.S. pork industry honored Roy Poage as the 2021 recipient of the Pork Industry Distinguished Service Award is long. By all accounts, he’s had more influence on modern day pork production than anyone. From pioneering “all-in/all-out” pig flows and implementing biosecurity measures before they were a buzzword, to creating the slatted floor system and developing swine production training manuals that are still used today, there’s no question Poage is passionate about pigs.

But Archer says that’s not why she nominated him.

“All of that is very impressive,” she concedes. “However, I nominated him because of the hundreds and hundreds of young people whose careers he launched in the pork industry – like mine. We're all aging, but we're still passing that information on to the next generation. His enduring legacy is the people that he sent out into the world who were really well-equipped to move the pork industry forward.”

Still, Poage’s journey to discovering new ways of raising pigs, perhaps unorthodox at the time, is critical to understanding how he led a revolution, developing some of the greatest minds in the swine industry today.

Roy and Kay (Liner) Poage say pig farming allowed their family to live out the "American dream." Photo provided by Poage.

From Geology to Pig Farming

Poage grew up in rural Texas and received a degree in geology from Texas Tech University in 1959.

“I always loved animals,” Poage says. “When my father-in-law asked me what I was going to do after college, I knew I did not want to go into geology. I wanted to get back into agriculture.”

He decided to take his father-in-law, the late T. Euel Liner, up on his offer to buy into a partnership on 20 purebred sows with the intent to sell breeding gilts to commercial producers. They bought a farm with 60 acres and built three confinement buildings with concrete floors.

Unfortunately, their venture didn’t start off well. Every morning, Poage would go out to the barn and find sick or dead pigs. He knew we couldn’t make a living raising pigs like that. Disease was getting out of hand as pigs were moved to indoor production. Around that time, he heard about a veterinarian in Iowa who was taking pigs by cesarean section and raising them in a lab setting to avoid disease passing on from the sow to her pigs.

“We went up to look at those pigs and it was unbelievable how healthy they were,” Poage says. “I said to my father-in-law, ‘If we’re going to be in the swine breeding business, this is the kind of healthy pig we’ve got to raise.’”

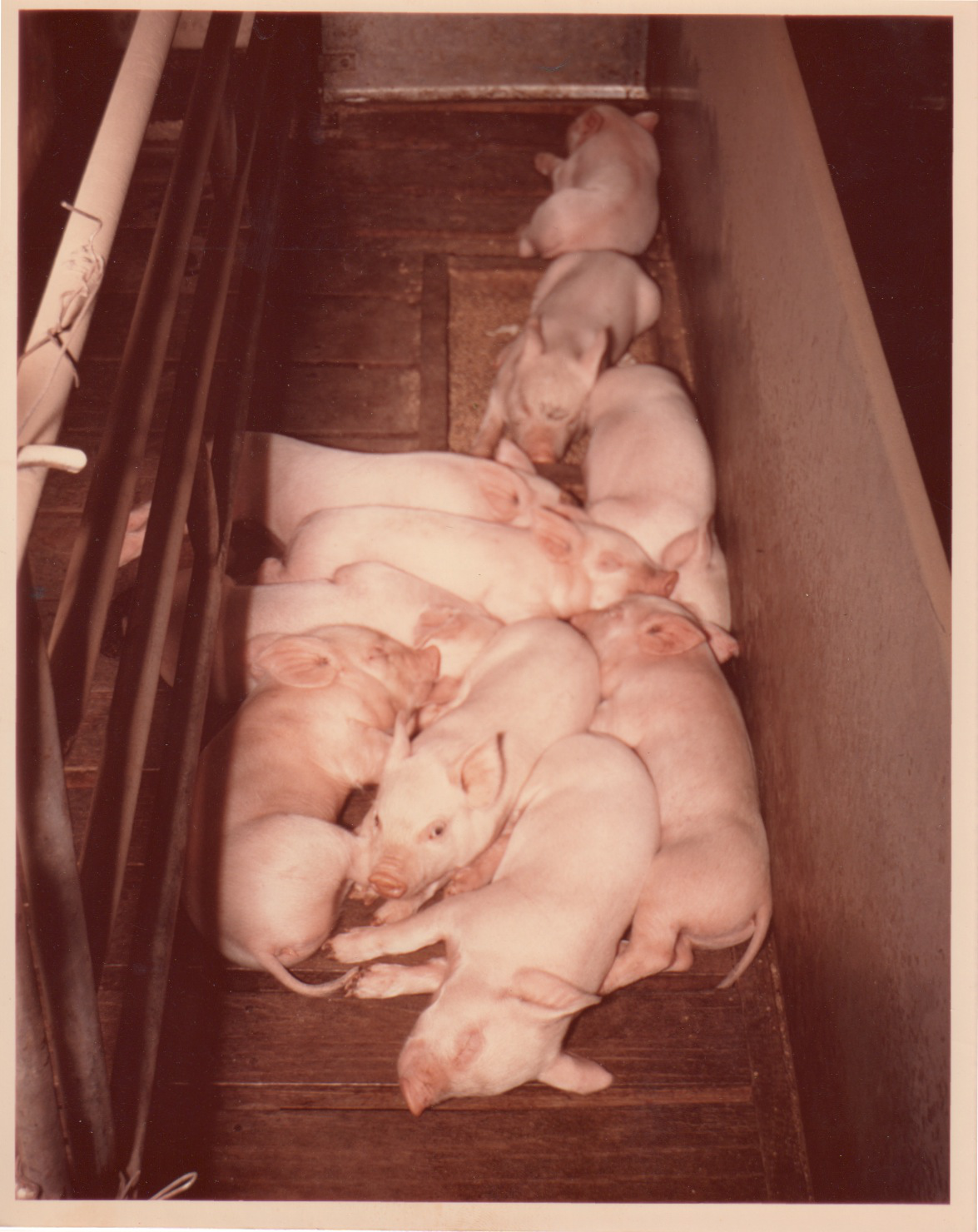

They returned to Texas and hired a veterinarian to build a lab and deliver pigs by cesarean section. They raised the pigs in boxes and hired Borden’s Milk Company to develop a sterile milk to feed those pigs for 30 days until they developed their own antibodies.

The boxes that Lubbock Swine Breeders used to rear the piglets after they were delivered. Photo provided by Poage.

In 1961, the two men founded Lubbock Swine Breeders on a farm near Posey, Texas. They brought the pigs raised in a lab setting back to the farm. During this time, Poage heard about a doctor in the Lake of the Ozarks who was raising worms for fishermen.

“He had this building with a slatted floor and all the feces dropped through,” Poage says. “That floor was just as clean as it could be.”

Poage brought that slatted floor system back to his farm and used wooden slats he purchased from the local lumberyard. That was just one of the many ideas that he had during those early years at Lubbock Swine Breeders that would go on to spur change in the pork industry.

"The pigs were so clean on those wooden slatted floors," says Roy Poage. Photo provided by Poage.

Outside interest grew in their production system. Before long, they started selling hog farms. Not only did they build the physical buildings, but they also sold the farm owners breeding stock, trained their staff and provided assistance in getting their operations up and running. Poage also developed Programmed Production, a set of procedures used to maximize production and consistency, to operate swine facilities more efficiently.

“These people had never raised pigs and we liked that,” Poage says. “People who had been raising pigs didn't like what we were doing and wanted to do it the old way.”

Of course, not everyone agreed with their approach at first. In fact, some people thought they were crazy, Poage says. Others said they just had a lot of money to spend and what they were doing would never amount to anything.

But Poage didn’t let that stop him. He went on to pioneer “all-in/all-out” animal flows where farrowing sows and pigs were segregated, and rooms were then thoroughly cleaned and disinfected between groups.

“We learned this practice from the chicken people. They would populate a house all in one day and then market all those chickens in one day. And when they did that, they would clean and disinfect that building and fumigate it before the next bunch came in. Because of this, they didn't transfer diseases from one generation to the next. We decided that's what we were going to do in pigs,” Poage says.

He collaborated with universities to develop these ideas into standard operating procedures and biosecurity protocols that have been broadly adopted across the industry and are still in use today.

An Unexpected Opportunity

Before college, Poage served in World War II in Germany. He purchased a camera and discovered a passion for photography. Whenever possible, he would snap pictures during the war. When he returned home, that interest grew, but with a new subject.

“I had people ask me to come make presentations about our pig business because they knew I took all these pictures of our farm and places I had visited,” Poage says. Over time, he began getting more invitations to speak, from feed companies to young swine enthusiasts, like Bill Prestage and Joe Luter who went on to build two of the largest and most successful pork operations in the country.

In 1972, the president of DeKalb Seed Company traveled down to Poage’s farm in Texas to invite him to lead their swine genetics business.

“They were the first company to hybridize corn, they hybridized chickens and they wanted to hybridize pigs,” Poage says. “They had built some pig farms in Illinois and had been working on it for a few years. But it wasn’t working.”

Although Poage wasn’t interested in moving, he agreed to go take a look at what they were doing in Illinois. Lubbock Swine Breeders was ready to expand, he says.

“We had proven that we had a workable system,” Poage says. “We didn’t have the money to expand like we needed to, so we decided to merge with DeKalb and traded our assets for stock in the company.”

They told Poage he wouldn’t have to move, but once he saw the support system they had at DeKalb, he was hooked.

“They had a big IBM mainframe computer, and we didn't even have a computer at our farm,” Poage says. “They had lawyers, accountants, everything that you need in business and a great support team. I knew I needed that kind of help.”

He got right to work building 19 farms throughout Kansas and Oklahoma with 1,200 sows per farm for DeKalb. He staffed them with college graduates, although he says he was never worried about what they went to college to study.

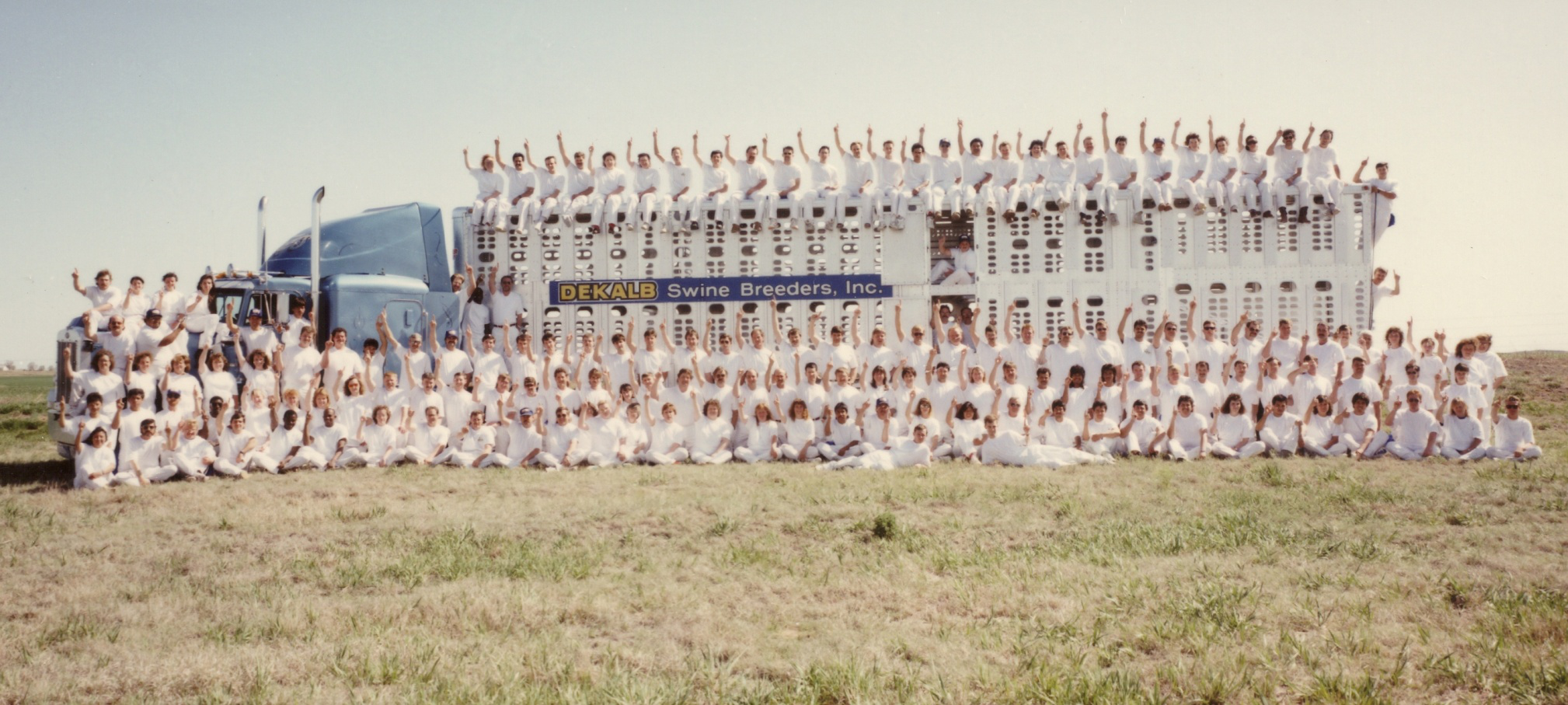

Farm managers and employees at the DeKalb Swine Breeders farm in Plains, Kan. Provided by Poage.

“In college, a professor told me that people like to hire college graduates because they have proven that they have the ability to study to learn something and solve problems,” Poage says. “I decided we’d hire college graduates and train them ourselves. One of our farm managers was an English major – it didn’t matter what they went to school for, it just mattered that they were teachable.”

DeKalb’s training program was named the National Best Employee Training Program by the National Bureau of Education Partnership. They were chosen over IBM, Caterpillar and Boeing in 1995, Poage says. As a result, the state of Kansas passed a resolution congratulating the Dekalb swine breeders on this honor.

Over the next 26 years, Poage grew DeKalb Swine Breeders into the second largest supplier of swine breeding stock and genetics in the world. He applied his leadership and innovation to transform the pork industry by continuing to use and spread the methods he developed while operating Lubbock Swine Breeders.

Do What You Love

“Raising pigs is very complicated,” Poage says. “There are so many things that you’ve got to have right that can go wrong. There's not any one thing that you can to do to make it all right. You have to get a lot of things right.”

That’s one of the reasons why Poage believes pig farming isn’t for everyone.

Keep reading to discover the advice Poage gave to a team of employees that led to three men quitting their jobs and a surprising revelation from Jan Archer, who nominated Poage for the Pork Industry Distinguished Service Award.