5 Things to Consider Before Adding Technology in the Swine Barn

By Suzanne Leonard, assistant professor and Extension specialist at North Carolina State University

Precision livestock farming technologies are rapidly being developed and increasingly available in the commercial market. These technologies can offer many benefits on swine farms, such as improved productivity tracking and reporting, reduced labor and improved sustainability and pig welfare. However, with so many technologies to choose from it can be challenging to decide which ones to invest in.

Even after determining a technology would have value, there are several other practical factors to consider when deciding if a technology might work within your production system. Here are five things to consider before you adopt new technology.

1. Hardware

Once you determine a technology is of interest, consider the physical infrastructure needed to accommodate the device. Most devices require specific placement in the barn to function properly, such as in the middle of the barn or directly over the center of a pen. Consider if your facility has the space to add the equipment without disrupting existing conduit, feed lines, ventilation systems and husbandry practices. Number and location of power outlets can be a limiting factor as well, especially for older facilities.

2. Cleaning and maintenance

If the devices need to be cleaned or serviced regularly, ensure they are readily reachable or removable. Even though a system may be marketed as plug-and-play with little maintenance required, rarely does that mean you can assemble and abandon it. Tune-ups and cleaning will be required from time to time to ensure proper operation and longevity. Some hardware is designed to stay in the barn and withstand routine cleaning and pressure washing. However, materials wear down over time with chemical exposure, so inquire about the specific types of cleaning and disinfecting products that can be used. If the technology is to be removed from the barn during cleaning, consider how it will be cleaned and where it can be safely stored when not in use. Any exposed wiring connections to the equipment that remain in the barn will likely need to be covered during periods of disinfection as well.

3. Communication protocols

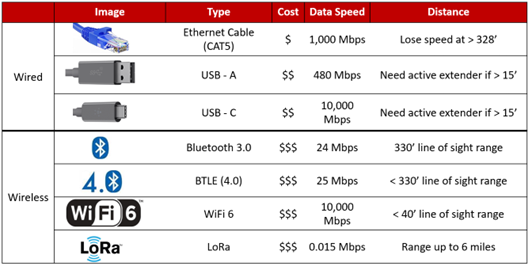

If multiple devices or access points are used, some form of connectivity will be required between them. Hardwired connections, such as USB or ethernet cables, can provide reliable and fast data transfer but require additional wires and conduit to be added in the barn. Wireless communication, such as WiFi or Bluetooth, does not require direct wires between devices but often needs additional repeaters or local data storage to work properly within the metal and concrete barn environment.

Figure 1. Common wired and wireless communication types and their approximate cost, data speed, and transmission distance. Source: Suzanne Leonard.

4. Internet connectivity

Any technology with remote monitoring capabilities or a “cloud” system will require internet connectivity. Though broadband coverage is steadily increasing in the U.S., it is not yet available in all areas. Satellite and cellular connections are reliable options in locations with clear sky or tower views. Consider how much data the system will actually be using and compare internet options. A video or camera system requires more data capacity and speed for remote monitoring, likely making an all-inclusive internet service package cheaper. However, for simple systems that remotely monitor a sensor’s value or a basic dashboard, a pay-by-usage or prepaid data plan might be cheaper. Some companies may include their own internet packages in their subscription fees, but it is important to be aware of how the data is being transmitted to ensure your barn location has enough signal strength for full technology functionality.

5. Human interactions

As most swine technologies aim to improve the human’s decision-making ability, the human-machine-interface, such as an app, monitor or software screen, will be how humans interact with the technology to check on its operation and gather information. The human-machine-interface is where users should spend most of their time with the technology, so be sure it is an interface that suits your system. Inquire about accessibility features such as extra-large font size or multiple language options to meet potential user needs.

Consider the technology and tasks it can do to determine the amount of human interaction you may need. Some technologies allow for multiple users simultaneously, for example an app that can be downloaded on multiple cell phones to enter farrowing performance data. Others have a single point of entry, such as one ventilation controller touchscreen. Depending on the technology and its purpose, you may wish to use password protection or user logins to manage and track who accesses, downloads, and changes information in the technology system. It may be beneficial to restrict user access to edit select items or read-only access to ensure only authorized personnel who are properly trained with the technology can make changes.

Purchasing swine barn technology is a major investment. No technology is perfect for every production system and scenario, but evaluating the practical factors of technology implementation can help you find the best technology for your own production system and goals.

Read More:

Barn Hero Summer Doty: Prioritizing Pig Care

Get the Facts Straight on Highly Pathogenic Avian Influenza